BRUNNER ENTERPRISES

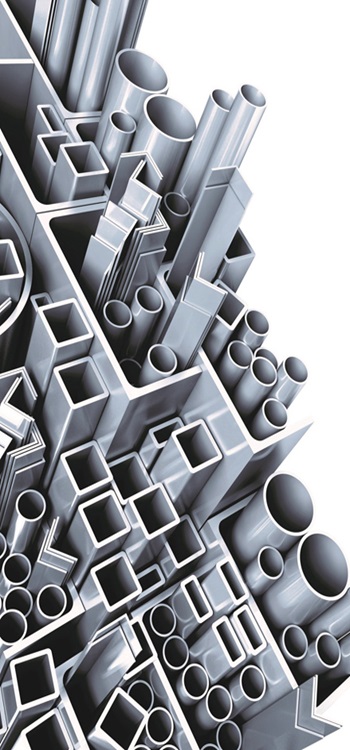

AMERICA‘S PREMIER DISTRIBUTOR OF ALUMINUM EXTRUSIONS

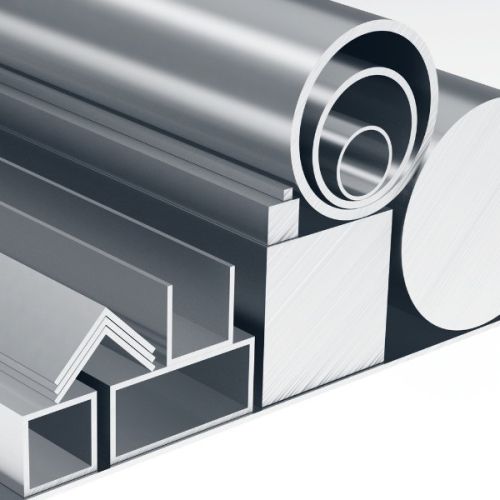

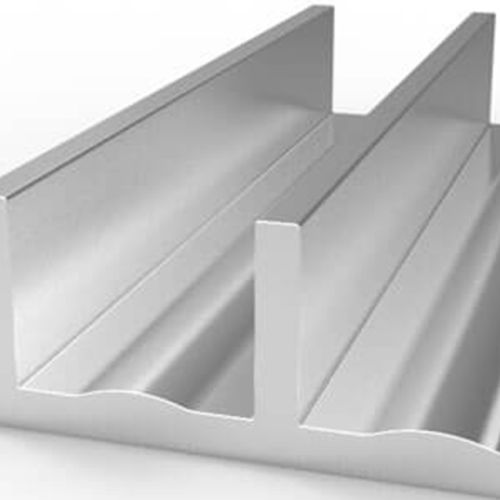

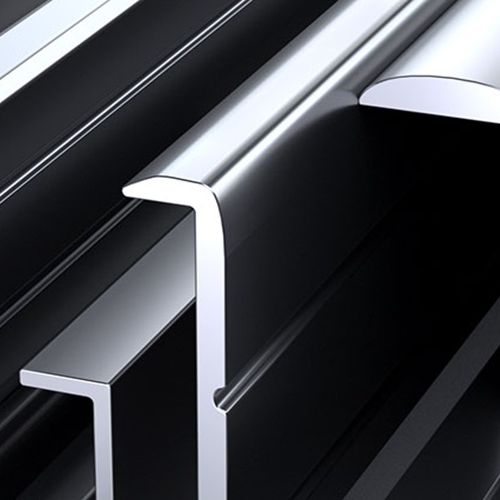

Aluminum has evolved into a stable and adaptable method for making aluminum shapes from simple to complex. Architectural millwork, marine, OEM, RV and trailer restaurants and hospitality, signs, specialty vehicles, store fixtures and displays, and custom applications all make use of aluminum extrusions.

Aluminum is frequently chosen as the material of choice for structural and building materials due to its strength, resistance to rust and corrosion, ease of fabrication, and 100% recyclable nature. Because it is malleable, aluminum can be easily formed, machined, and cast. Aluminum is a material that can be used in a lot of different ways and is cheap.

…OUR GOAL IS TO PROVIDE A SUPERIOR PRODUCT AT A FAIR PRICE.

What Are The Advantages of Aluminum Extrusions

- Affordable – Cost effective material and less expensive than other metal forming processes.

- Attractive Finishes – Aluminum can be anodized, polished, buffed.

- Conductive – Aluminum is a very good conductor of electricity.

- Corrosion Resistant – Protects against corrosion by making a thin reactive layer to oxygen.

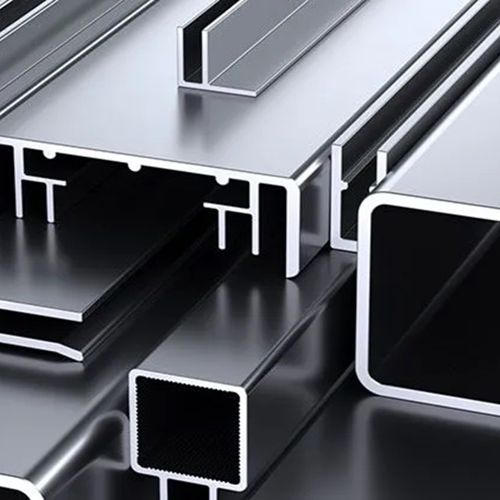

- Customization – Aluminum extrusions are the preferred material in product solutions.

- Expansion – Has a large coefficient of linear expansion.

- Highly Reflective – Reflective for visible light and finish options.

- Heat Conductive – Dissipates heat, perfect for heat shielding applications

- Lightweight – Aluminum is about one-third the weight of steel, iron, brass, and copper.

- Low Maintenance – Naturally resistant to corrosion, does not require a protective layer.

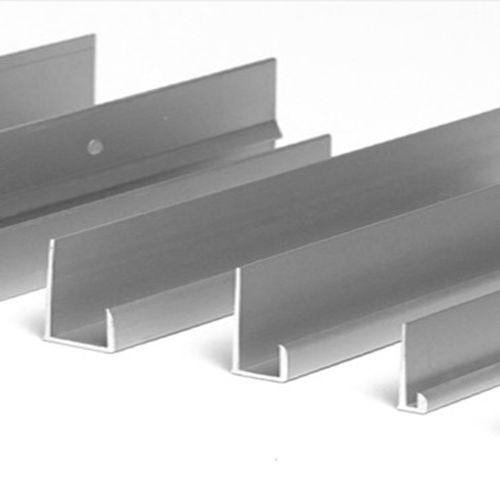

- Malleable – Aluminum is easy to form, extrude, and machine into complex shapes.

- Non-toxic – Commonly found material and used safely.

- Paramagnetic – Avoids interference of magnetic fields when used in magnet x-ray devices.

- Precise – Can conform to very tight or close tolerances.

- Quality – Uniform quality when extruded and contains no mechanical joints.

- Recyclable – 100% recyclable. Aluminum can be recycled indefinitely without losing its structural integrity. Nearly 75% of all aluminum ever produced is still in use today.

- Strong – Aluminum extrusions are very strong and a high tensile strength range. Aluminum is very good for cold weather applications and becomes stronger as the temperature falls.

- Time-to-Market – Creating aluminum tooling is easier, reducing lead times in manufacturing.

Custom and OEM aluminum extrusions are manufactured, stocked, and provided by Brunner Enterprises™ Inc. In the event that we don’t have the expelled aluminum part that meets your determinations, our experts will help you make and specialist one to address your issues. We are able to satisfy nearly all of our customers’ aluminum extrusion requirements thanks to our custom and OEM extrusion services. Get in touch with our knowledgeable support staff right away.