BRUNNER ENTERPRISES

AMERICA‘S PREMIER DISTRIBUTOR OF ALUMINUM EXTRUSIONS

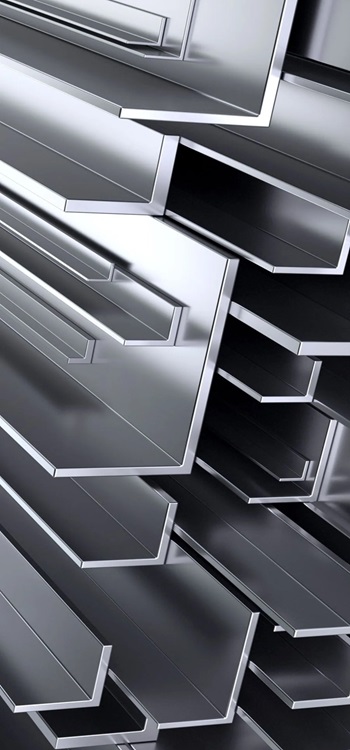

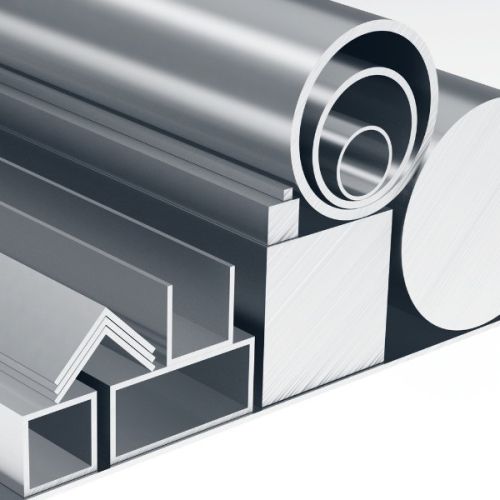

The process of shaping aluminum is known as the aluminum extrusion process. A raw aluminum form known as a billet or log of aluminum is used in the extrusion process. After being heated to a predetermined temperature, the aluminum is made malleable and soft before being transferred to a press container. The aluminum billet is then squeezed through a die in the final shape by the press as it pushes it through the container with a lot of pressure. After that, the part that was extruded goes through a number of stations, where it can be cooled, stretched, and cut to the length that you want. The die is an essential part of the extrusion process that allows the aluminum to take the shape it wants. Continue reading to learn more about the various aluminum extrusion dies available and their roles in the manufacturing process.

What Are Extrusion Dies?

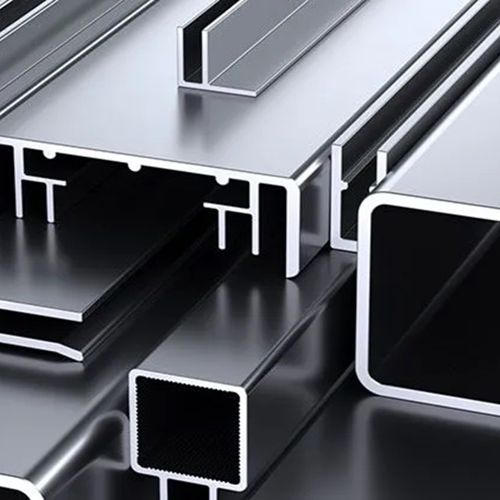

The dies that are used in the aluminum extrusion process can be made into almost any shape that the user wants. Ordinarily, the pass on will be produced using an exceptionally sturdy steel material that includes an initial slice through it. In most cases, the steel will undergo heat treatment to ensure that it can withstand the high pressure and temperatures of the hot aluminum that is being extruded. Because it contains the precise shape and size of the intended cross-section for the finished extruded aluminum products, the opening of the die plays a crucial role in the production of aluminum extrusions. Extrusion dies generally fall into two main categories: empty passes on and strong (or level kicks the bucket). A solid die will produce a solid extruded aluminum shape, whereas a hollow die will produce a hollow piece of aluminum. There is likewise a choice to make a kick the bucket that includes a mix of the strong and empty passes on if necessary.

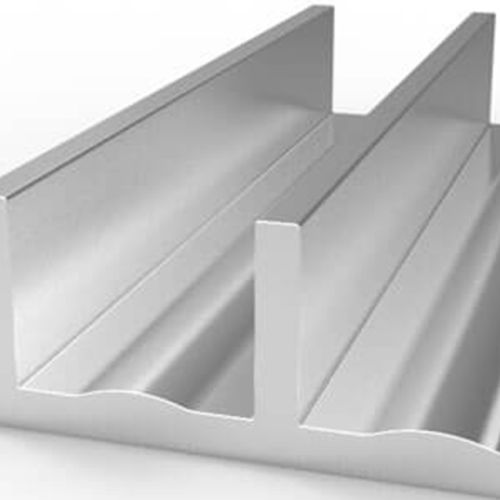

Solid Dies

The principal reason for a strong bite the dust is to make an expelled aluminum piece that is a solitary, strong piece – implying that you won’t track down any encased voids or semi-empty circumstances. All things considered, strong bites the dust include one or potentially more openings or holes through which the warmed and relaxed aluminum will be expelled. When compared to other types of die, solid aluminum extrusion dies are typically the less expensive option for the aluminum extrusion process and can produce aluminum angles, channels, flat stock, or rods. The solid profile known as the “die stack” is made possible by a collection of steel plates working together, which include: the feeder plate which controls the progression of aluminum through the pass on opening; the actual shape-forming die plate; the bolster to support the extrusion load transmitted from the backer and die, as well as the backer plate, which supports the die and aids in preventing shape distortion or collapse.

…OUR GOAL IS TO PROVIDE A SUPERIOR PRODUCT AT A FAIR PRICE.

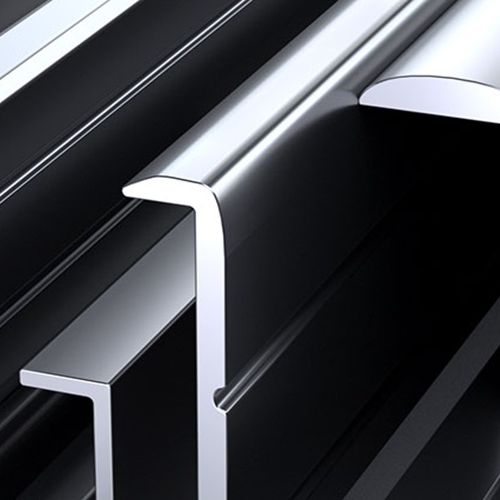

Hollow Dies

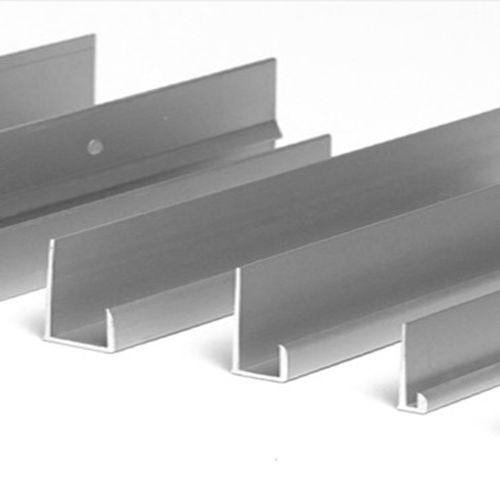

Empty passes on produce a profile that highlights at least one voids – like a basic cylinder with a solitary opening, or more intricate expelled aluminum pieces with various point by point voids. There are various different empty pass on structures, with the most well-known being openings, extensions, and bug bites the dust. Manufacturing costs and approaches used vary greatly due to their potentially complicated designs. A hollow die’s die set is different from a solid one because it has a mandrel inside the die with two or more portholes, a die cap to form the shape, and a bolster to hold the extrusion load in place.

SEMI-Hollow Dies

By only partially enclosing a void during the aluminum extrusion process, semi-hollow aluminum extrusion dies can produce aluminum that is nearly hollow. In addition to die caps and bolsters, semi-hollow die die sets will include a mandrel with portholes.

Custom and OEM aluminum extrusions are manufactured, stocked, and provided by Brunner Enterprises™ Inc. In the event that we don’t have the expelled aluminum part that meets your determinations, our experts will help you make and specialist one to address your issues. We are able to satisfy nearly all of our customers’ aluminum extrusion requirements thanks to our custom and OEM extrusion services. Get in touch with our knowledgeable support staff right away.